|

|

| Treadle and Vintage Singer Models |

|

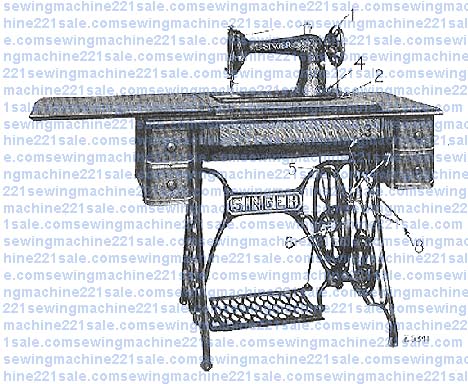

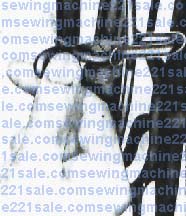

HOW TO SHORTEN OR REPLACE A TREADLE BELT NOTE: If the old belt is still on the machine examine closely the routing of the belt. OR, cut the old belt, holding both ends, and tape one end of new belt with one end of old belt and pull through belt routing. Also, new treadle belts come 72 inches in length and are designed to be cut and custom fit to each particular machine set-up. How to shorten a belt: To shorten a belt already on the machine, open the hook at the joint, remove one end of the belt from the hook, pull the slack and make a mark for cutting. After cutting the surplus, punch a small hole in the newly cut end and insert the hook: before tightening the hook test the belt for proper tension to be sure it has been shortened sufficiently. How to replace a belt: First put one end over the balance wheel (1,Fig.32), making sure it goes down into belt groove of balance wheel, and comes out the front under the bobbin winder. Then continue down through the front hole in the metal lifter plate (2, Fig.32) and out through the hole (3) in the wood shield. Pull through about 12" of the belt to prevent the end slipping back through hole 3. Next, working from the back of the machine, put the other end of the belt through the rear hole (4) in the metal lifter plate, through belt guide (5), between band wheel and brace (6) and through belt shifter (7, Figs 32 & 33). Pull the slack from both ends forward to (8) and bring belt to a tighten position and make a mark for cutting. (Note: a new belt will stretch and require shortening much sooner than an old one and should therefore be applied a little tighter than usual). After cutting the surplus, punch a small hole in the newly cut end and insert the hook, but do not flatten the hook. Now operate the treadle to test the belt tension and if not too loose, flatten the hook so it does not project beyond the belt. If it is necessary to shorten the belt to secure proper tension throw it off the band wheel by using the belt shifter (7,Figs 32&33) pull forward to (8), unlock hook, shorten belt a little, re-hook and test again. It is most advantageous to have a belt-punch to care for and replace belts properly. Such a belt-punch as shown in Fig. 34, will cut a belt and punch the hole in one operation. The pliers on the end of the punch will serve to loosen the wire hook and tighten it again. It is also well to have on hand a small quantity of belt hooks for repairing belts. PLEASE Check our web site: www.sewingmachine221sale.com for treadle belts, hooks, belt-punch and other sewing supplies.  Fig 33 Belt Shifter  Fig 34 Pliers Fig 34 Pliers |

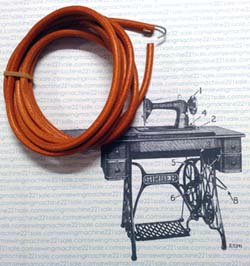

Treadle Leather Belt with Metal Hook #804-M/W (965512)(#8)

Treadle Leather Belt with Metal Hook #804-M/W (965512)(#8)$10.95 The highest quality leather treadle belt available. Fits all treadles Singer and non-Singer. Comes 3/16" diameter X 72" long with clip. Designed to be cut to fit. Comes with FREE instructions on "How to shorten or replace a leather treadle belt". Eight step method for proper routing, measuring, cutting and adjusting of a treadle belt. For additional important information on adjusting the treadle mechanism/stand see "Sewing Machine Maintenance Manual (1944)". ADD BASIC S&H [Add to Cart] [View Cart] |

Treadle Belt Hooks #818-17 HD (BH8-PD)

Treadle Belt Hooks #818-17 HD (BH8-PD)Set of 2 $1.95 Special note: These replacement hooks are heaver in diameter then what comes in the treadle belt #804 M/W. They are not particularly better just heaver in diameter. These are the ONLY hooks available. Sold in set of 2. ADD BASIC S&H [Add to Cart] [View Cart] |

Treadle Belt Plier #425/6 (811)(119-6)****No Longer Available****

Treadle Belt Plier #425/6 (811)(119-6)****No Longer Available****$0.00 ****No Longer Available**** Use for cutting and punching hole for treadle belt #803-M / 804-M SPECIAL NOTE: The pliers are considered FREIGHT INTENSIVE (F/I)... They DO NOT qualify for FREE S&H. Make sure when checking out you DO NOT click on the FREE S&H... $8.95 is the basic S&H for ALL FREIGHT INTENSIVE (F/I) items [Add to Cart] [View Cart] |

Mini Precision Screwdriver Set (Bin T-4)

Mini Precision Screwdriver Set (Bin T-4)$12.95 Small compact set includes convenient bit holder Set includes 18 different bit ends: Slotted: 1/8", 3/32", 5/64", 5/64", 1/16" Phillips: PH000, PH00, PH00, PH0, PH1 Torx star: T4, T5, T6, T7, T8, T9, T10, T15 Depending on current inventory this item may very in color and / or brand ADD BASIC S&H |

Tweezers #TWE6

Tweezers #TWE6$3.95 Top quality tweezers with guide pin 6" long with bent point design. The best tool in your accessory box. Ideal for threading needles on sewing machines and needles and loopers on sergers. Many other practical sewing uses: removing thread and lint build-up from small areas in the sewing machine, pulling out unwanted stitches, etc. ADD BASIC S&H [Add to Cart] [View Cart] |

Small Tools, Driver Set with Offset Ratchet (Bin-T-1)

Small Tools, Driver Set with Offset Ratchet (Bin-T-1)$24.95 Sewing machine and other small appliances require different tools than your car or home This set is a great place to start Set contains one each: reversible ratchet handle, spinner screwdriver handle, 3 1/4" extension handle One each of the following bits Slotted screwdriver: 1/8", 1/4" Phillips screwdriver: PH#1, PH#2 Hex: .050", 1/16", 5/64", 3/32", 7/64", 1/8", 9/64", 5/32", 3/16", 7/32", 1/4", Torx: T6, T8, T10, T15, T20, T25 ADD BASIC S&H |

Torx Bit Set 5" Long with Thin Shaft (Bin T-2)****No Longer Available****

Torx Bit Set 5" Long with Thin Shaft (Bin T-2)****No Longer Available****$0.00 ****No Longer Available**** Sewing machine and other appliances require a long thin shaft for getting into confined areas 5" long with a standard 1/4" hex shaft Set includes one each: T6, T7, T8, T9, T10, T15, T25, T30, T40 ADD BASIC S&H |

Torx Bit Set Small (Bin T-3)

Torx Bit Set Small (Bin T-3)$13.95 Hard to find Torx bits, standard 1/4" hex shaft Set includes: T4, T5, T6, T7, T8, T9, T10, T15, T20, T25 ADD BASIC S&H |

Operator Maintenance Kit

Operator Maintenance Kit$12.95 *High quality oil in refillable extendable spout. Long neck spout style of oiler #NK2 may vary depending on availability. *Lubricant for gears *Lint brush *Extra fine quality screw driver for tension adjustments *2 strips of crocus cloth for removing burs on hook, etc. *6" abrasive cord #52 for removing burs in and around needle plate, etc. *Oil and lubricant instructions pamphlet for various models ADD BASIC S&H [Add to Cart] [View Cart] |

Email: sewingmachine221sale@pop.bizland.com

This web site is owned and operated by:

Discount Sewing Machine Service ©2000

Site contains material that are trademark TM and servicemark SM.

All material is for personal use only and is not to be mass produced.

Pages constructed and maintained by Kas