|

|

| Sewing Machine Motors |

|

Service Level:

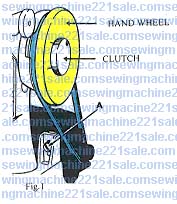

#1 Clean, Oil &Adjust (SL-1) lubricate motor, oil entire machine, check for build up of lint in feed dog area, adj. pressure, check and adj. stitch regulator etc. See your instruction manual. #2 Check Belt Tension (SL-2) see Fig. 1: Tension on the belt should be just enough to keep the belt from slipping. If the belt is too tight, the machine will run slowly. This will overload and possibly damage the motor. TO ADJUST:

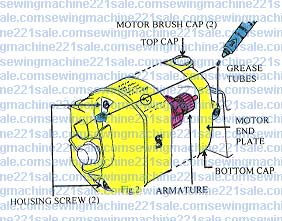

If after the above checks and adjustment you have not been successful in increasing the speed and power of your machine it is now time to consider motor maintenance or replacement. MOTOR MAINTIANANCE: In preparing this service page I checked the r.p.m. (revolutions per minute) of all the machines I serviced last week. Even after a complete cleaning, oiling and general servicing I found a considerable difference in various models in their r.p.m. Most differences however were related to the different size of the diameter of the hand wheel (from 2,500 r.p.m. to 1,200r.p.m.) In this group of 15 three were featherweights (1,500 r.p.m.; 1,700r.p.m.; 1,800r.p.m.). Featherweights in there nature are not intended to be fast and powerful however 1,500r.p.m. would be a good benchmark to go by. Many Featherweights I have serviced over the years were much slower than 1,500r.p.m. and I was in most cases able to bring them up to acceptable performance some I did have to replace the motor .Try some of these procedures before you consider a motor replacement. NOTE THE FOLLOWING MAY BE CONSIDERED SL-2 & SL-3, IF YOU DO NOT FEEL KNOWLEDGEABLE OR COMFORTABLE WITH THESE PROCEDURES, TAKE MACHINE AND CONTROL TO YOUR SERVICE TECHNICIAN NOW:

|

Oiler with Extendable Spout, Contains 1oz of Oil #NK2

Oiler with Extendable Spout, Contains 1oz of Oil #NK2$4.95 Oil, lilly white, no wax will not gum-up over long periods of use. Comes with 4" extendable spout to reach into tight areas. Apply this oil sparingly where metal moves against metal. Long neck spout style of oiler may vary depending on availability. Do not oil the motor, use lubricant #S-2129 ONLY on the motor as instructed in your manual or as information found in the operators maintenance kit. ADD BASIC S&H [Add to Cart] [View Cart] |

Singer Lubricant: #S-2129 (190613)

Singer Lubricant: #S-2129 (190613)$4.95 Singer lubricant, tube Reformulated (white in color) for metal and synthetic parts Use on motor hub ports and metal gears. Consult your manual for information or information found in the operators maintenance kit. ADD BASIC S&H [Add to Cart] [View Cart] |

Lint brush: #S-2110

Lint brush: #S-2110$1.25 Long flexable handle with long stiff brush to remove lint and dirt from hard to reach areas. ADD BASIC S&H [Add to Cart] [View Cart] |

|

Brush Seater: #CBS5 $11.95 For cleaning armature, medium abrasive, for better seating. ADD BASIC S&H [Add to Cart] [View Cart] |

|

Armature cleaner: #AC6254 $11.95 Cleans, removes dirt & polishes armature, very light abrasive. Diamond D Rubrite ADD BASIC S&H [Add to Cart] [View Cart] |

|

Armature resufacer: # AC204 $11.95 Armature resufacer, hard abrasive, removes uneven copper. ADD BASIC S&H [Add to Cart] [View Cart] |

Motor Brushes (set of two): #192457

Motor Brushes (set of two): #192457$15.95 Motor brushes with copper springs. Brushes come in a set of two. This is the ONLY old style motor brush still available. It may fit the following models: 221, 201, 15-91, 301, 401, 403, 404, 500 Slant-O-Matic series, 600 Touch & Sew series, 700 Touch & Sew series and possibly some other models. NOTE: On some models it may be necessary to gently file down all four edges of these motor brushes to make them "Free Fitting" in the motor brush housing. Remember these are the ONLY motor brushes available for older model Singers. ADD BASIC S&H [Add to Cart] [View Cart] |

221 Belt #194144 Black

221 Belt #194144 Black$12.95 Belt for the 221 Featherweight ALSO see the New Style Featherweight belt #194144N.S. ADD BASIC S&H [Add to Cart] [View Cart] |

Double Lead #714179 (123)(bin 43)

Double Lead #714179 (123)(bin 43) $24.95 For machines requiring one electrical cord for both power, 74" long and foot control cord, 56" long. Models may include: 15-88, 15-90, 15-91, 27, 66, 201, 221 222, and some 301-A which do not use a seperate cord for the foot control (197628/9). ADD BASIC S&H [Add to Cart] [View Cart] |

Single Lead #197874 (122)(bin 44)

Single Lead #197874 (122)(bin 44) $22.95 For machines requiring two electrical cords. This one is for power only, cord 72" long. Your machine will have two pins, the cord has three holes, however the center hole of the cord is inactive. Models may include: 301, 319, 401, 403, 404 You should have a different cord for the foot control (see #197628) Also fits some 15 class/201 and other models mounted in cabinet with seperate wire from terminal box (192797) to foot control. ADD BASIC S&H [Add to Cart] [View Cart] |

Foot Control Cord (bin 45) #197628 (197629)(783)

Foot Control Cord (bin 45) #197628 (197629)(783)$9.95 For models: 301, 401, 403, 404 Cord is 62" long. These models require electric cord #197874 ADD BASIC S&H [Add to Cart] [View Cart] |

221 Motor 110volt #98376-004 Black

221 Motor 110volt #98376-004 Black $139.95 Fits Featherweight 221 and 222 New by Alpha-Sew motor (no longer available by Singer). Black original style, standard USA 110-120 volt. Input 70Watt, 0.4 amp., 25-75 cycles, 5500 R.P.M. This item does not qualify for the $45.00 free freight offer. It is F/I Freight Intensive choose $8.95 for S&H [Add to Cart] [View Cart] |

Refurbished Original Singer Motor

Refurbished Original Singer Motor$0.00 OUT of STOCK Resurface, polish and clean armature. Replace motor brushes, clean and lubed. Present motor has 29,000 R.P.M. (see "FREE Service" Motor Maintenance) This item does not qualify for the $35.00 free freight offer. It is F/I Freight Intensive. On the order page choose $6.95 for S&H [Add to Cart] [View Cart] |

Manual for Singer 221with "Free" Bonus Parts Chart

Manual for Singer 221with "Free" Bonus Parts Chart $19.00 New enhanced reprint of the original manual with larger text for an easy read. Also includes instructions for using the attachments, contains information on operator adjustments, cleaning and oiling. 64 illustrations, over all measurement is 8 1/2" X 11", 67 lb. card stock front and back covers for durability. As an added bonus we will include a parts chart for models 221-1, 221K1, 221K4, 221K5, 221K7. NO return on manuals. ADD BASIC S&H |

Singer Service Manuals

Singer Service Manuals Operator Maintenance Kit

Operator Maintenance Kit Mini Precision Screwdriver Set (Bin T-4)

Mini Precision Screwdriver Set (Bin T-4) Tweezers #TWE6

Tweezers #TWE6 Small Tools, Driver Set with Offset Ratchet (Bin-T-1)

Small Tools, Driver Set with Offset Ratchet (Bin-T-1) Torx Bit Set 5" Long with Thin Shaft (Bin T-2)****No Longer Available****

Torx Bit Set 5" Long with Thin Shaft (Bin T-2)****No Longer Available**** Torx Bit Set Small (Bin T-3)

Torx Bit Set Small (Bin T-3)